As we move towards a more technology-driven world, the fabrication of permanent magnets has become paramount to the success of various technological advancements. Ndfeb magnets, short for neodymium-iron-boron magnets, are one of the most popular types of permanent magnets in use today, with their superior magnetic properties being one of the main reasons for their use. In this blog post, we will take a deep dive into the magnetic properties of Ndfeb magnets, and how they are used to produce electrical material.

Ndfeb magnets are made up of three primary elements; neodymium, iron, and boron. They have a tetragonal crystal structure, which makes them highly magnetized compared to other materials. Ndfeb magnets, specifically, have a maximum magnetic energy product of up to 55 MGOe (mega-gauss-oersted), making them the most powerful magnets presently available in the market.

One of the most important considerations when working with Ndfeb magnets is their magnetic strength. At room temperature, the remanence of Ndfeb magnets (the strength of the magnetic field they retain once the external magnetic field has been removed) can range between 1.09 and 1.45 tesla (T). The coercivity of Ndfeb magnets (the strength of the magnetic field required to demagnetize them) ranges between 810 and 2890 kA/m. These values vary depending on the composition of the magnet and the manufacturing process applied.

Ndfeb magnets exhibit a high temperature coefficient of magnetic properties, which can affect their performance in high-temperature environments. As the temperature increases, the strength of the magnetic field decreases, and the magnetic properties of the magnet deteriorate. The Curie temperature of Ndfeb magnets (the temperature at which the magnet loses its magnetic properties) is approximately 310°C. Therefore, when working with Ndfeb magnets, it is important to consider the environment in which they will be operating to ensure optimal performance.

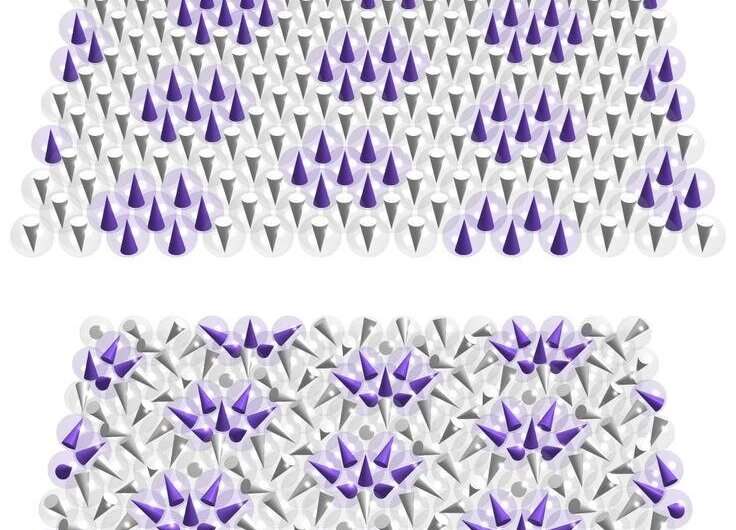

Another important property of Ndfeb magnets is their anisotropy. Ndfeb magnets are made of magnetic particles that are uniformly aligned along the crystallographic axis of the tetragonal structure. This anisotropic alignment causes Ndfeb magnets to exhibit a strong magnetic field along the direction of the axis and weak magnetic fields along the lateral directions.

Ndfeb magnets are available in different grades, which differ in their magnetic properties. The most common grades of Ndfeb magnets include N35, N38, N42, N45, N50, N52, N54, N56, N58, and N60. The number following the letter 'N' in the grade indicates the maximum energy product of the magnet in MGOe. For instance, the higher the number, the stronger the magnet. N52 is the most commonly used Ndfeb magnet grade as it provides an excellent balance between magnetic strength, stability, and cost.

The magnetic properties of Ndfeb magnets make them highly suitable for various electrical applications, including generators, motors, magnetic separators, and sensors. Ndfeb magnets are also used in wind turbines, hybrid cars, and hard disk drives, among other applications.

In conclusion, Ndfeb magnets' magnetic properties make them an excellent choice for permanent magnet applications where high magnetic strength and stability are required. When working with Ndfeb magnets, it is essential to understand their magnetic strengths, anisotropy, and temperature coefficients to ensure optimal performance. Understanding the properties of Ndfeb magnets will help improve the development of the electrical material, which includes the production of permanent magnets.